How can we define the manufacturer's expectations from cutting tool producers? Cutting tool producers are expected to provide optimal cutting tool solutions for a given application. So, how is an optimal cutting tool defined for a specific application? It is obvious that standards must be set to achieve a formidable solution. Cutting tool standards are also defined by principles to enable choosing the best possible tool for a given application. Technical literature often states one tool or another as being optimal for an application. Therefore, a clear definition of the optimality standard is essential.

The criteria for finding the optimal cutting tool depends on various factors. The type of manufacturing (short-run, large-scale, mass), product range, machined materials, machinery used, cutting strategies and more have a direct impact on the manufacturer's selection of the most effective tool. The manufacturer is interested in a tool that guarantees the highest performance levels. This can be achieved by optimizing the tool geometry and producing the tool from the most relevant cutting material grade. But the chosen geometry and grade are tool key elements associated with the type of machined material. So, what is the ideal tool for cutting? An example of an effective tool for machining cast iron, will most probably not be the best solution for machining heat-resistant superalloys.

Manufacturers are faced with constant dilemmas for machining vast choices of workpieces of different shapes and dimensions. The profile of a given application may dictate a long-reach tool, whereas in other cases the large overhang of the tool will have forced limitations that decrease machining stability which inevitably affects performance.

Selecting the optimal tool is one segment of many that relate to the core of the problem critical for all machining processes, which no doubt maximizes how to machine profitability. To reach this goal, various interdepended factors are considered such as the effective use of machine tools, competent process planning, available work-holding fixtures, and tool stock management among others. All factors are subject to optimization and finding the appropriate tool may prove to be an integral link to accomplishing the task.

Modern production abilities feature highly engineered CNC machine tools with advanced capabilities. New age premium machines are costly and reduce machining cycle time which in turn diminishes production costs. An ideal cutting tool should provide maximum productivity in combination with reasonable and stable tool life. To determine the appropriate solution, tool manufacturers develop advanced cutting geometries and new cutting material grades that enable reliable cutting at high metal removal rates (MRR) for diverse types of machining data. As the tool is expected to enable effective machining of different engineering materials, the geometry and the grades should be optimized accordingly.

Decreasing machine downtime is one more way to reduce production costs. The appropriate waymarks, which relate to tool attributes such as ensuring tool availability and minimizing setup time, can greatly contribute to the solution. Tool delivery is crucial for replacing "optimal" with "suitable".

By saying, "the best tool is the one you have on hand", one can understand important metalworking principles, making the ideal tool readily accessible.

In a perfect world, the ideal tool facilitates machining various workpiece shapes on long- or short-reach applications without loss of performance. Tool customizing is an additional parameter for finding the optimum solution.

Advanced machines are expected to integrate optimal machining strategies. These strategies are planned, programmed, checked, and verified in a virtual environment of computer-assisted engineering (CAE) systems well before the process begins on a CNC machine. Therefore, the right tool should have an appropriate virtual component, a digital twin, to be embedded in CAE systems.

The wide array of ISCAR's new products, introduced in the NEOLOGIQ campaign, is aimed at optimizing tool solutions for modern metal cutting. The NEOLOGIQ principles are conveyed by the use of new tool and insert geometries complemented by advanced grades. Among the many new developments, there are tools for Swiss-type lathes and multitasking machines.

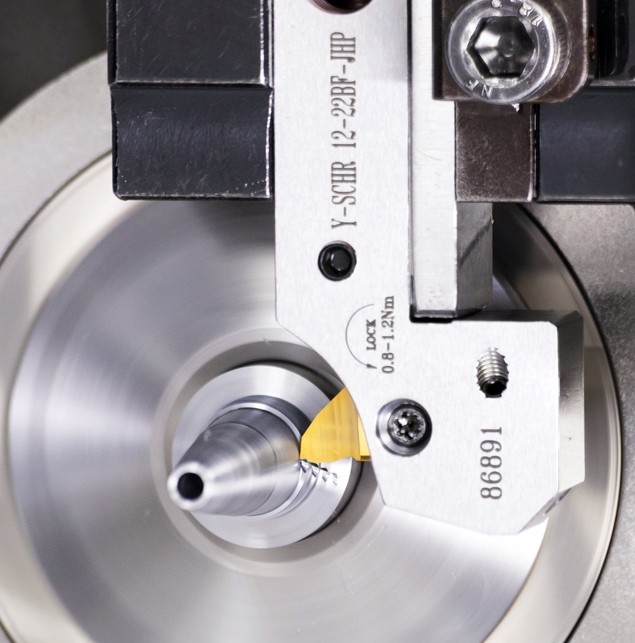

Stainless steel and non-ferrous metals are common materials for manufacturing miniature parts in the medical and watch industries. Small and medium-size Swiss-type lathes are used for mass part production. A new generation of ISCAR's ISO-standard rhombic turning inserts is specifically intended for this industry sector. A variety of precision ground and polished inserts enable productive machining with light cutting forces and significantly reduced friction (Fig. 1). The cutting geometry is represented by two types of chipformers intended for semi-finishing, finishing, and roughing. The insert design with its many geometric attributes is focused on preventing built-up edge to ensure prolonged tool life.

ISCAR has developed two new carbide grades for milling different engineering materials effectively. IC716 is intended for machining titanium alloys. It is characterized by a tough cemented carbide substrate with high resistance to thermal cracks and a new high-hardness ceramic PVD coating with a smooth surface. IC5600 is designed for cutting steel. This grade features a submicron substrate, a multi-layer MT CVD coating, and an applied post-coating treatment. This combination substantially improves the resistance of IC5600 to abrasive wear and thermal loading and enables increasing cutting speeds and MRR.

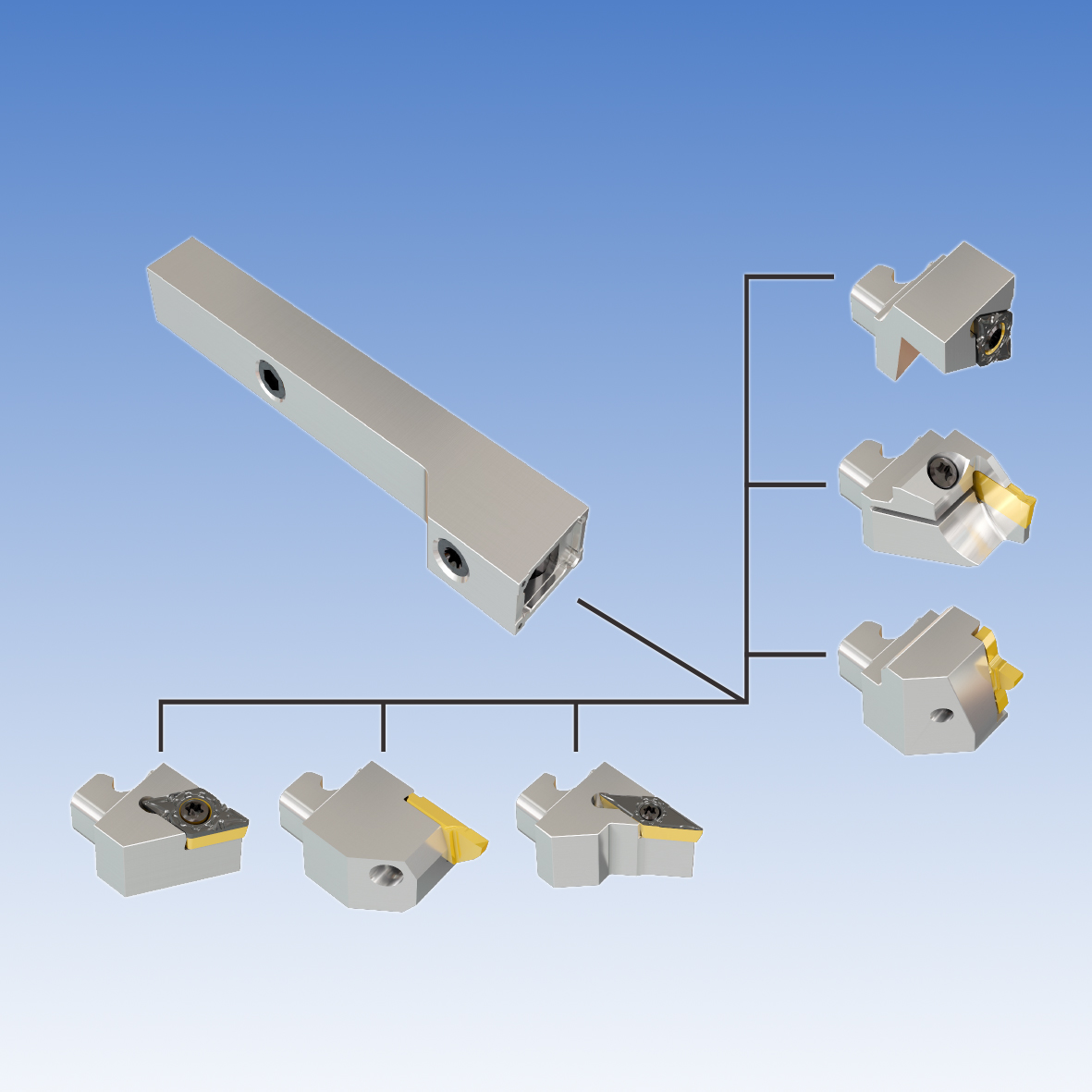

The development of machine tools has made Y-axis turning methods common. These methods facilitate extremely stable cutting and enable the evacuation of long chips in a downward direction due to gravitational force. It is apparent that the metalworking industry increases its demands for advanced cutting tools specially designed for Y-axis turning. One of ISCAR's prominent new product lines is the NEO-Y-SWISS line of integral turning tools. (Fig. 2). A modular tool concept that utilizes a tool assembly based on standard elements such as holders, heads, shanks, extensions, reducers, etc., is an effective way to find the optimal tool for specific applications. The distinctive feature of ISCAR's new modular quick-change heads system NEOSWISS is comprised of diverse heads with indexable inserts for turning, grooving, parting, and threading operations on Swiss-type machines (Fig. 3). This system enables removable heads and insert replacement in the limited working space of a CNC machine.

To stay up to date on modern age machining, ISCAR accentuates rotating tools with exchangeable cutting heads such as MULTI-MASTER and CHAM-IQ-DRILL. These modular lines with the "No Setup Time" phenomenon, enable quick head replacements that annul dimensional adjustment and CNC program corrections. This diminishes machine downtime and assures high machining repeatability. The modular design concept of ISCAR tool lines makes customizing tool configuration easy.

A significant functional improvement features ISCAR's tool digital companion; 3D and 2D tool representations, tool assembly options, advanced E-Catalog and additional application software form the backbone of the virtual tool environment. ISCAR's Tool Advisor, known as NEOITA, enables searching for an optimal tool for a specific machining operation. Based on engineering analysis and expert knowledge, this system generates a set of more efficient solutions with suitable cutting data, calculates MRR, cutting power, etc., and enables direct access to the e-Catalog, insert wear detection, and more.

A new responsive design application has brought NEOITA to handheld devices. Through cloud-based technology, the NEOITA is available 24/7 and in multiple languages (Fig. 4).